ASTM E2315 Time-Kill Test

Get A Testing Quote

With Microchem Laboratory a Liquid Suspension Time-Kill test procedure is highly versatile and catered directly to the study sponsor’s needs.

ASTM E2315: Procedure at a Glance

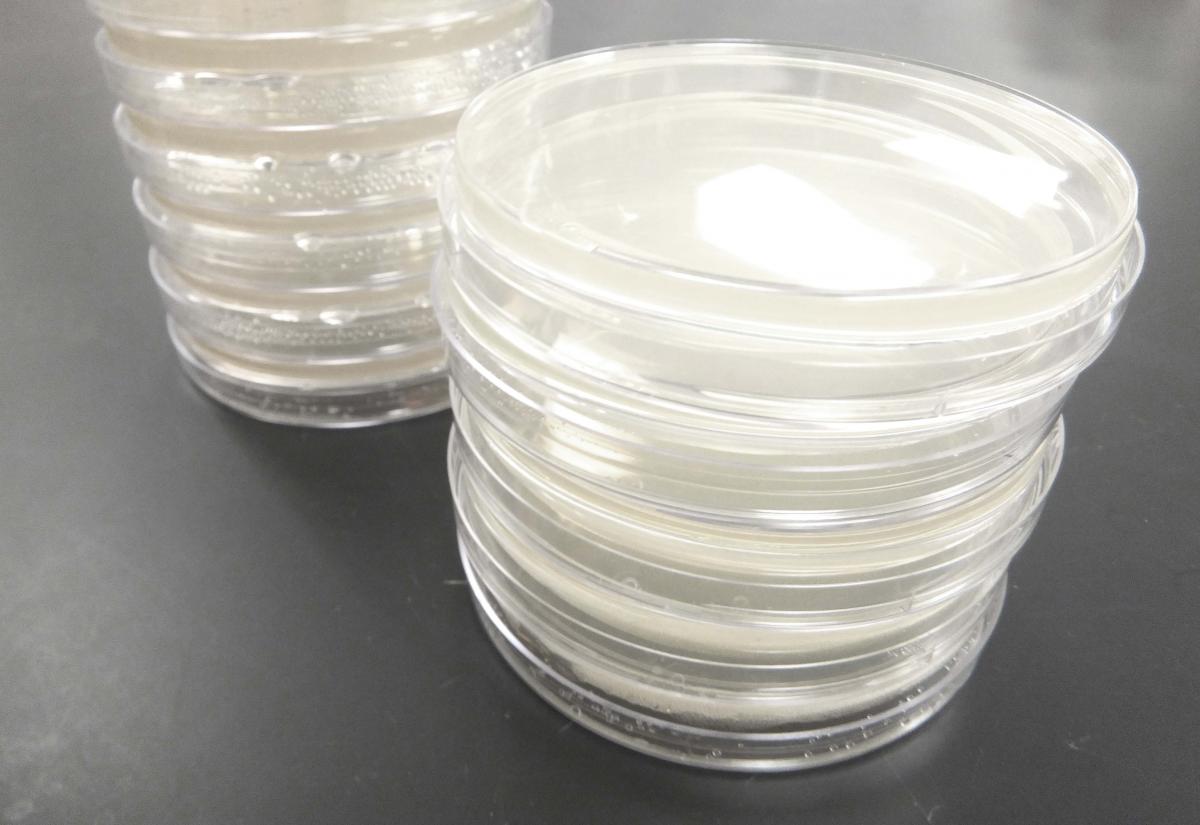

The Liquid Suspension Time-Kill begins with the direct inoculation of a volume of the disinfectant in question with a specified representative organism. After a specified contact time the system is neutralized and the presence of microorganisms is monitored and quantified following a period of incubation. The microbial growth is compared to that of an untested enumeration control to determine the total reduction.

To zero in on the minimum effective contact time for the disinfectant at tested conditions, multiple contact times can be used. From the resulting data, a slope of the disinfectant’s kill-rate is produced. Beyond that, many different test parameters can be altered to better match the real-world use of the disinfectant. These include temperature, the ratio of disinfectant to inoculum, the “soil load,” and many other possibilities.

Due to the direct contact between disinfectant and inoculum, the Liquid Suspension Time-Kill is most adept at modeling the efficacy of disinfectants used in liquid or submersion settings; however, the Liquid Suspension Time-Kill is often tested at an R&D level to gather preliminary, best-case data on a disinfectant’s antimicrobial efficacy.

ASTM E2315: Microchem Laboratory’s Expertise

Microchem Laboratory has a long history of performing the Liquid Suspension Time-Kill, gathering reproducible data that study sponsors can count on.